Paper

Structure of large closed calcium carbide furnace and treatment of common equipment faults

Updated: 2022-04-28 Attention:快盈11v

With the rapid growth of PVC output, the demand for calcium carbide is also increasing, which has greatly improved the existing equipment and technology level of China's calcium carbide industry. In calcium carbide production, calcium carbide furnace occupies a very important position. At present, calcium carbide furnaces at home and abroad can be divided into open calcium carbide furnace, semi closed calcium carbide furnace and fully closed calcium carbide furnace according to furnace type, with large capacity and closed calcium carbide furnace as the main development direction. At present, Tianneng Chemical Co., Ltd. (hereinafter referred to as Tianneng chemical) has a calcium carbide production capacity of 640000 T / A. the core equipment calcium carbide furnace is contracted, produced and installed by Dalian heavy industry Electromechanical Equipment Co., Ltd. there are 12 calcium carbide furnaces in total. The furnace type of calcium carbide furnace is fixed fully enclosed calcium carbide furnace.

The production process of calcium carbide is a complex process of process control, and all links affect each other. There are many unforeseen factors in the process control link, including high-temperature smelting, chemical reaction and physical changes, which makes the design of calcium carbide furnace more complex, there are many points and surfaces to be considered, and the internal structure of furnace body is also more complex. Tianneng chemical calcium carbide furnace is equipped with ecs-700dcs distributed control system of Zhejiang central control technology Co., Ltd., with a high degree of automation. Since it was put into operation in August 2010, due to the advanced management and maintenance level of the whole set of calcium carbide furnace production device, the production is stable, safe, high production efficiency and relatively low energy consumption, which effectively improves the production and operation capacity of the equipment and plays a great role in improving the output and quality of products.

Process and control facilities

1.1 process

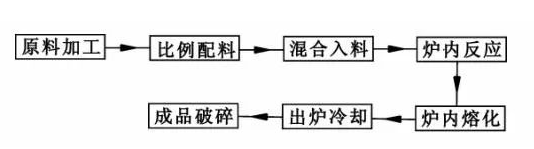

At present, the production methods of calcium carbide in China include aerobic heating method and electrothermal method. At present, Tianneng chemical uses the electrothermal method to produce calcium carbide, that is, a certain proportion of raw materials quicklime and coke generate calcium carbide by arc high-temperature melting reaction in the calcium carbide furnace. The main production process is: distribute the weighed mixture of limestone and coke into the silo as required through the furnace top distribution facility, and then add it into the calcium carbide furnace in batches through the calcium carbide furnace feeding pipe. After a certain time, the molten calcium carbide after reaction is transported to the cooling room by tractor in the calcium carbide pot for cooling, cooled to 30 ~ 40 ℃ and solidified into calcium carbide lump, and then hoisted into the calcium carbide crushing platform by crane for crushing. Qualified products are sent to the finished product warehouse by bucket elevator. The carbon monoxide generated in the reaction is purified and comprehensively utilized by the post sequence section of calcium carbide furnace. The production process of calcium carbide can be briefly described as shown in Figure 1.

Fig. 1 block diagram of calcium carbide production process

1.2 control facilities

Tianneng chemical adopts ecs-700dcs distributed control system of Zhejiang central control technology Co., Ltd., and the whole system of calcium carbide furnace realizes automatic control. On the premise of fully considering the production process characteristics of the whole set and the hardware and software advantages of the computer control system, and in accordance with the principles of stable production, safety and reliability and advanced technology, this set of automatic control system adopts the advanced electric control system design scheme of the three in one of control system computer, electric drive and automatic instrument. For example, the automatic control of electrode pressure release and lifting of calcium carbide furnace, automatic constant power and constant current regulation of calcium carbide furnace are coordinated by the respective automatic control system of each calcium carbide furnace. The use of the automatic control device improves the working performance of the calcium carbide furnace; The whole system has a high degree of automation, which reduces the process and equipment errors caused by manual operation and reduces the labor intensity of operators; Stable production, safety and environmental protection, received good results, and raised the production process level of calcium carbide furnace to a very high level.

Main equipment structure and common fault treatment

Calcium carbide furnace is an extremely complex equipment, which is mainly composed of discharge system, cooling water system, electrode system, hydraulic system, secondary bus system (short network system), blanking system, etc. Each part supports each other, and the factors of each part will affect the normal operation of the whole system.

2.1 discharge system

(1) Composition.

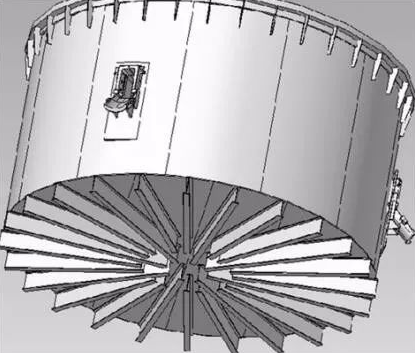

The discharging system is composed of furnace body (furnace shell), furnace bottom I-beam, furnace door frame, furnace tongue, discharging track, cast steel guide rail, calcium carbide pot, calcium carbide trolley, winch, etc. Figure 3 shows the appearance structure of the discharge system. The main function of the discharge system is to make the molten liquid calcium carbide mixture flow into the calcium carbide pot, and then transported by trolley to the calcium carbide cooling shed for cooling and crushing.

Fig. 3 appearance structure diagram of discharge system

(2) Common faults in the installation and maintenance of discharge system. In the preliminary construction, the installation of on-site furnace bottom I-beam is very important. In the discharge system, the I-steel at the bottom of the furnace is the base support of the calcium carbide furnace and cools and dissipates heat at the bottom. The bottom plate of the furnace is a basic component. In the production process, the bottom plates of the three outlet ports should be protected to prolong the service life of the bottom of the furnace, so as to ensure the normal operation of other systems of the calcium carbide furnace in the future. The I-beam can be installed and leveled only after the tolerance dimension of the furnace bottom foundation is calibrated with a level gauge. After the I-beam is installed, the horizontal tolerance dimension can be rechecked with a level gauge.

2.2 cooling water system

(1) Composition.

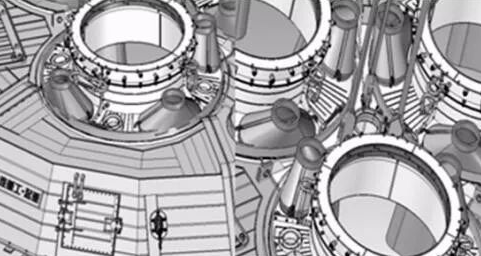

Figure 4 shows the structural diagram of cooling water system and furnace cover.

Fig. 4 structural diagram of cooling water system and furnace cover

The cooling water system and furnace cover are composed of furnace cover (6 sections, water cooling structure, lower knotting refractory), electrode sealing guide sleeve (3 sets, stainless steel water cooling structure, lower knotting refractory), central triangular beam (stainless steel water cooling structure, lower knotting refractory) and water distributor (3). Its main function is to cool the parts required to be cooled by the whole system.

(2) Common faults and preventive measures.

There are two common faults: ① the overflow of furnace gas and the entry of air caused by sealing fault affect the purity of furnace gas. ② Due to the accumulation of sundries in the gap between parts, the phenomenon of power connection and fire between equipment occurs, which seriously affects the normal production. This fault is mainly caused by improper sealing treatment.

The sealing function of furnace cover is very important. Figure 5 shows the detailed structure diagram of furnace cover and water system. For the 6-SECTION furnace cover in the furnace cover, insulating mica plates are required between each section, and the connecting bolts are sleeved with mica pipes and mica insulating pads. It is required that each section of furnace shell must be insulated. There are refractory bricks under the electrode sealing guide sleeve, which play the role of insulation and sealing, and there are insulating plates or refractory seals between the furnace covers. When making the furnace cover, the top and side of the interior shall be made of a whole steel plate to reduce the probability of steel plate splicing and welding and the leakage of the furnace cover from the interior; The water channel is made outside. The water channel is completed by steel plate bending to reduce weld and water string. The external steel plate is sealed and welded. For the furnace cover under repair, when the knotted refractory has been burned and fallen off, it is necessary to re weld the reinforcement pile for knotting, and then repair the damaged water channel. Recheck the sealing of each part on the furnace cover and conduct the final inspection.

In the cooling water system, the role of electrode water-cooling sealing sleeve is also very important. In production, after the electrode sealing sleeve is adjusted, do not adjust the position at will. During maintenance, it shall be noted that after the insulation treatment between the sealing sleeve and the furnace cover is completed, there shall be no more metal sundries, and the material column shall be sealed well. The upper part of the water-cooled sealing sleeve shall be insulated by flange; Three sets of water distributors are used to centrally distribute cooling water for various equipment requiring cooling on the calcium carbide furnace. If the return water volume of a single pipeline is found to be small during maintenance, check whether the valve is closed in good condition and whether the dead corner of the equipment pipeline gathers scale and other sundries. These subtle sealing treatments are extremely important.

2.3 electrode system

(1) Composition

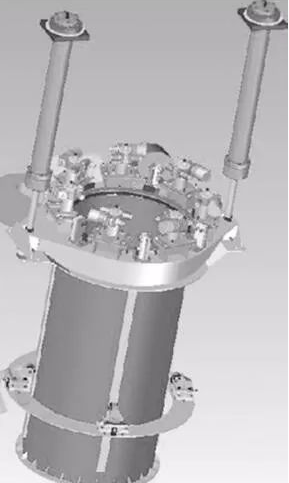

The electrode system is composed of electrode column, electrode shell, electrode pressure release platform and hydraulic clamp, conductive copper pipe and contact element, short net, water-cooled cable, bottom ring and water-cooled protective screen. Fig. 6 is the structural diagram of the electrode system. The combined electrode column is composed of upper and lower parts. The main function of the electrode system is to transmit power and adjust the smelting arc length, matching current and voltage, so as to achieve the best smelting efficiency.

In daily production, the progressiveness of calcium carbide furnace is mainly reflected in the technology of combined electrode holder. The combined electrode holder is the core technology of the closed calcium carbide furnace, including the conductive holder and the pressure release electrode clamp. Its main characteristics are that it can be used for electrodes of any diameter to accelerate electrode roasting, the electrode shell will not deform, the electrode will not be out of control during pressure release, reduce electrode breakage, light equipment quality, low maintenance cost, less operation accidents and high comprehensive economic benefits.

(2) Common faults and treatment measures

In case of major potential safety hazards due to insulation failure, it is necessary to check whether the flange insulating plate and insulating pipe are intact, whether the contact element and conductive copper pipe are leaking, whether the clamping force of the contact element and electrode shell is adjusted properly, and whether there are impurities in the gap, which may lead to insulation failure. For the daily maintenance of the electrode system, strengthen the daily inspection and replace the insulating parts in time to ensure the normal production. During shutdown, thoroughly check the insulation damage of all parts and replace them in time. Strictly clean the sundries at the connection of all equipment (such as iron parts, oil products, etc.) to prevent irreparable loss to the whole system caused by power connection and ignition.

2.4 hydraulic system

(1) Composition

The hydraulic system is mainly composed of pump station, electrode pressure release plate (valve station), strong cylinder, clamping cylinder, etc. its main function is to provide power for electrode lifting and pressure release. Figure 7 is the structural diagram of the hydraulic system.

(2) Common faults

When the hydraulic clamp, accident clamp and electrode column guide device, the main components of the hydraulic system, are working, if there are metal sundries on their surface or oil leakage inside and outside, they can cause production safety accidents with electricity and fire.

2.5 secondary bus system (short network system)

(1) Composition

Whatsapp

Whatsapp