Paper

Principle of submerged arc furnace and main parts and devices

Updated: 2022-04-28 Attention:快盈11v

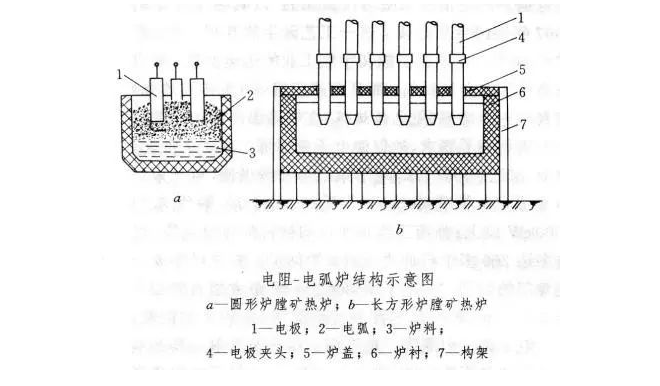

Its working feature is to use refractory as furnace lining and self baking electrode. The electrode is inserted into the charge for submerged arc operation. The energy and current of the arc are used to pass through the charge, and the energy generated by the resistance of the charge is used to smelt the metal. It is an industrial electric furnace for continuous operation with continuous feeding and intermittent iron slag discharge.

1.2 metallurgical principle of submerged arc furnace

The basic task of submerged arc furnace production is to extract useful elements such as metals from ores or oxides. The chemical reaction in the production process of submerged arc furnace is mainly the reduction reaction of oxide, but also the oxidation reaction of elements.

1.3 submerged arc furnace process

The submerged arc furnace is fed into the furnace intermittently through the feeding device, the furnace rammer maintains the material surface, is equipped with opening equipment such as hole opener or arc burners, opens the iron port, and the liquid alloy flows into containers such as molten iron ladle, and then transported to the mold for pouring. After cooling, the products are put into the finished product warehouse. The iron slag is discharged intermittently through the slag outlet.

1.4 classification and application of submerged arc furnace

The power consumption varies greatly with the composition of raw materials, the composition of finished products and the capacity of electric furnace. Here is the approximate value.

矿热炉主要零部件

It is mainly composed of furnace body, furnace cover, short net, water cooling system, smoke exhaust system, dust removal system, waste heat treatment system, electrode shell, electrode pressure release and lifting system, loading and unloading system, controller, burnthrough device, hydraulic system, submerged arc furnace transformer and various electrical equipment.

Furnace body

The electric furnace body is composed of furnace shell and refractory lining.

The furnace shell is composed of furnace bottom plate, furnace wall plate, hoop and rib plate. The furnace shell adopts circular structure, the side plate of furnace shell adopts thick steel plate, and the support is channel steel supported on concrete.

The lining of electric furnace lining adopts high alumina, magnesium soil and carbon refractory materials; First grade magnesia bricks and magnesia materials are used near the outlet, combined with refractory materials such as carbon silica bricks.

Furnace shell

The requirements for the furnace shell are: the strength shall meet the severe expansion caused by the heating of the furnace lining, adapt to the requirements of the heat rise and cold contraction of the furnace lining, and strive to save materials and facilitate manufacturing.

An iron tap is integrated on the furnace shell.

Furnace cover

The furnace cover of the sealed furnace takes the water-cooled steel beam as the framework and is built with refractory bricks and refractory materials. The three electrode holes on the top of the furnace cover are mainly used to let the three-phase electrode holder pass through the furnace and insulate the electrode holder from the furnace cover with insulating materials. The furnace cover is provided with 9 thermometer sockets, which are inserted into the refractory brick with a protective tube. Insert the thermometer into the protective tube to measure the furnace steam temperature in the furnace cover.

Smoke hood

The function of the smoke hood is to close the furnace mouth, block the radiant heat, collect the flue gas produced in the smelting reaction process and improve the operating environment. The smoke hood is composed of cover plate, side wall, furnace door, smoke hood framework, etc. The smoke hood is formed by welding steel plate and profile, which is hexagonal. Sit on the operation platform through the smoke hood skeleton.

Flue gas outlet pipe

The function of the flue gas outlet pipe is to form the negative pressure in the low smoke hood by the natural pressure difference or the fan of the dust collector to realize the external smoke exhaust. Each electric furnace is equipped with two flues, which are made of steel plates and profiles. The flue consists of lower water cooling section, flue pipe section, bell valve and flue hanging.

The water cooling section at the lower part of the flue is located on the beam ring of the low smoke hood, which is cooled by water. The smoke pipe section is divided into several sections and directly leads to the outside of the roof. A bell valve is arranged on the flue opening outside the roof, which is used to close the flue. The bell valve is opened and closed by the flue oil cylinder. When it needs to be connected to the dust collector, close the bell valve, and the flue gas will be sent to the dust collector through the tee under the action of the fan.

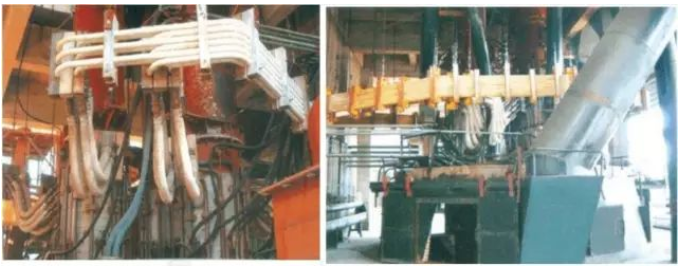

Electrode holder

Electrode holder is the core equipment of submerged arc furnace. It is composed of conductive device, holding device, pressure release device, lifting device, holding cylinder and electrode shell. The electrode holder mainly makes the copper tile close to the motor shell under appropriate pressure through the holding device to ensure that the large current transmitted from the short network passes through the collector support of the collector ring or electrodeless ring and the conductive copper tube to the electrode through the copper tile.

At present, the equipment level of submerged arc furnace in China varies greatly, and there are many types of electrode holders. At present, the electrode holder used in China can be distinguished according to the type of holding device. There are radial screw clamped grippers, large bolt clamped grippers, cone ring grippers, combined or standard component grippers, bellows grippers, etc.

Holding cylinder

The holding cylinder is one of the important components in the holding system. The holding cylinder, also known as the electrode outer cylinder, is used to suspend the electrode holder and the electrode, and can raise and lower the electrode during operation.

Conductive device

Traditional conductive devices generally include collector rings, conductive copper tubes and copper tiles. The collector ring is mainly used to equalize the voltage, collect the current, and then distribute it to the conductive copper pipe, so that the current of each copper tile on each electrode is basically equal Copper tile is the main component that sends electric energy to the electrode. The copper tile is cast with red copper, and there is a cooling water pipe inside. The allowable current density of the contact surface between the copper tile and the electrode is in the range of 0.9 ~ 2.5a/cm2. The height of the copper tile is about equal to the electrode diameter. The number of copper tiles can be calculated according to the current of each phase of the electrode. The electrode sintering belt is the weak link of the whole electrode strength. The holding force of the copper tile to the electrode is 0.05 ~ 0.15Mpa, and the contact pressure comes from the electrode holder. The electrode with combined holder is helpful to improve electrode sintering.

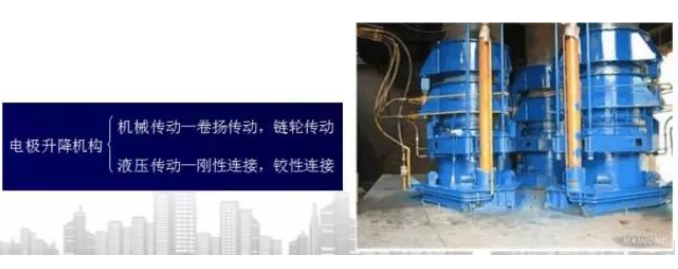

Electrode lifting device

Whatsapp

Whatsapp